Why Precision Engineering Matters in Mining?

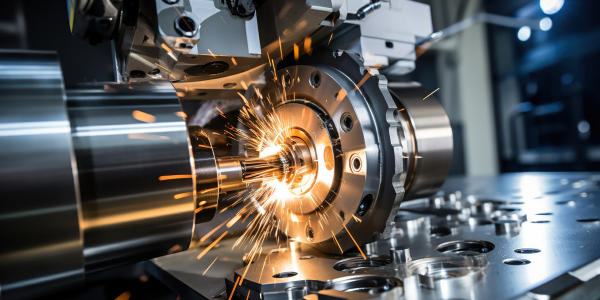

In Adelaide and across South Australia, when it comes to Mining CNC machining, reliability isn’t optional — it’s the foundation of success. Every drill machinery component and honing system has to perform under extreme conditions, where even the smallest error can cost thousands in downtime. That’s why mining companies across Australia trust Precision engineering to keep their equipment safe, dependable, and efficient.

Mining is one of the toughest industries on earth. Equipment faces constant exposure to dust, heat, vibration, and heavy loads. Without precision-engineered parts, machines wear out faster, safety is compromised, and production slows down.

At Gaja Engineering, our focus on Mining CNC machining ensures every component — from drill assemblies to honing systems — is manufactured with accuracy, consistency, and durability.

CNC Machining for Mining Applications

Our advanced CNC machining services give mining companies an edge by delivering parts that meet strict standards. Here’s how we support your operations:

- Drill Machinery Components – Strong, reliable, and designed to keep drilling systems running smoothly.

- Honing Systems – Manufactured with extreme precision to improve efficiency and extend the service life of mining equipment.

- Wear-Resistant Parts – Built to withstand constant abrasion, reducing replacement frequency and downtime.

With multi-axis CNC machining, we achieve complex geometries and deliver consistent quality across small or large production runs.

Supporting Heavy Industry with Reliable Machining

For mining operations, downtime is costly. That’s why our precision machining services are built around three core principles:

✔️ Drill Machinery Components – Strong, reliable, and designed to keep drilling systems running smoothly.

✔️Honing Systems – Manufactured with extreme precision to improve efficiency and extend the service life of mining equipment.

✔️Wear-Resistant Parts – Built to withstand constant abrasion, reducing replacement frequency and downtime.

With multi-axis CNC machining, we achieve complex geometries and deliver consistent quality across small or large production runs.

Why Choose Gaja Engineering for Mining CNC Maching?

-

Local expertise in Adelaide, South Australia with a proven track record in heavy industry.

-

State-of-the-art facilities for CNC machining, fabrication, and welding under one roof.

-

ISO-certified processes and rigorous inspection systems.

-

Collaborative partnerships where we refine designs for better performance and cost-effectiveness.

When you need more than a supplier — when you need a trusted partner in mining equipment manufacturing — Gaja Engineering is here to deliver.

🔧 Your Local Adelaide Engineering Partner

Looking for CNC machining Adelaide, hydraulic repairs, or fabrication services South Australia?

Gaja Engineering is your trusted partner for precision-engineered solutions that keep your business moving.

Frequently Asked Questions (FAQ)

1. What is CNC machining in mining?

CNC machining uses computer-controlled equipment to cut and shape mining components with extreme accuracy, ensuring reliability in harsh conditions.

2. Why are honing systems important for mining equipment?

Honing systems improve durability and performance by ensuring smoother surfaces, reducing wear, and extending equipment lifespan.

3. What materials are best for mining CNC machining?

We commonly machine hardened steels, stainless steels, and wear-resistant alloys that handle vibration, dust, and heavy loads.

4. How does precision engineering reduce mining downtime?

Accurate machining produces stronger, longer-lasting parts that reduce failures and keep operations running without interruption.

5. Why choose an Adelaide-based manufacturer like Gaja Engineering?

Local expertise means faster turnaround, clear communication, and solutions built for Australian mining challenges.