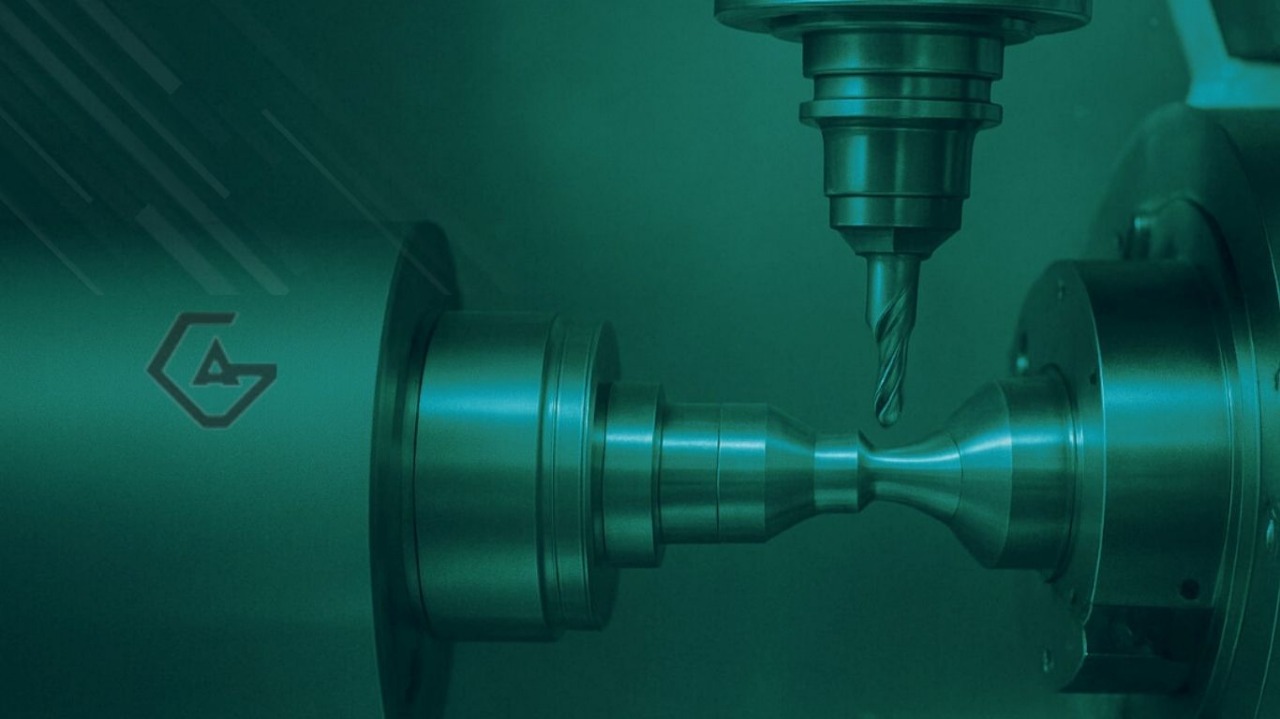

In today’s competitive manufacturing industry, efficiency, accuracy, and cost savings are top priorities. One of the most impactful innovations driving these results is the CNC Mill-Turn Machine. By integrating complex milling and turning operations into a single setup, manufacturers can dramatically reduce downtime, improve precision, and optimize production for high-demand industries such as aerospace, automotive, oil & gas, and medical components.

Why CNC Mill-Turn is a Game-Changer

Traditional machining often requires multiple setups—moving parts between a lathe for turning and a mill for cutting. This not only adds time but also increases the risk of errors and alignment issues. CNC Mill-Turn Machines solve this by combining both processes into one seamless operation.

-

Key benefits include:

- Single Setup Efficiency: Eliminates the need to transfer workpieces, saving valuable time.

- Enhanced Accuracy: Ensures higher precision with fewer chances of misalignment.

- Cost Reduction: Reduces labor, material handling, and setup costs.

- Versatility: Ideal for complex geometries, high-volume production, and custom parts.

By reducing cycle times and ensuring tighter tolerances, CNC mill-turning boosts productivity and enables companies to deliver superior-quality parts consistently.

Applications of CNC Mill-Turn

From Multi-Axis Aerospace Components to Automotive Engine Parts and Customized Industrial Fittings, mill-turn machining allows for efficient production of intricate designs that would be otherwise time-consuming and costly.

Why Choose Gaja Engineering for Mining CNC Maching?

-

Local expertise in Adelaide, South Australia with a proven track record in heavy industry.

-

State-of-the-art facilities for CNC machining, fabrication, and welding under one roof.

-

ISO-certified processes and rigorous inspection systems.

-

Collaborative partnerships where we refine designs for better performance and cost-effectiveness.

When you need more than a supplier — when you need a trusted partner in mining equipment manufacturing — Gaja Engineering is here to deliver.

🔧 Your Local Adelaide Engineering Partner

Looking for CNC machining Adelaide, hydraulic repairs, or fabrication services South Australia?

Gaja Engineering is your trusted partner for precision-engineered solutions that keep your business moving.

Frequently Asked Questions (FAQ)

1. What is a CNC mill-turn machine?

A CNC mill-turn machine is a hybrid system that combines milling and turning functions, enabling both operations in one setup.

2. How does CNC mill-turn improve efficiency?

It reduces setup changes, lowers production time, and minimizes errors, making it faster and more cost-effective.

3. Which industries benefit most from CNC mill-turning?

Industries like aerospace, automotive, oil & gas, defense, and medical device manufacturing benefit significantly due to their need for complex, high-precision parts.

4. Is CNC mill-turn suitable for small batches?

Yes, its flexibility makes it suitable for both prototype development and large-scale production.

5. How does Gaja Engineering use CNC mill turn?

We use it to machine complex shafts, custom parts, and repair equipment with higher precision and shorter turnaround times.

6. How do we reach Gaja Engineering?

You can reach out via the contact page or call our team to discuss your project scope.