Maximising Operational Uptime with Expert Hydraulic Cylinder Repair in Adelaide

In the demanding environments of mining, infrastructure, logistics, and utilities, the performance of hydraulic systems plays a crucial role in operational continuity. Hydraulic cylinders, being the workhorses behind lifting, pressing, and motion systems, are subjected to immense pressure and wear. When these cylinders fail unexpectedly, the result is often an immediate halt to operations, leading to significant downtime, production loss, and unplanned maintenance expenses.

At Gaja Engineering, we specialize in hydraulic cylinder repair in Adelaide, offering end-to-end servicing for industrial clients across South Australia and surrounding regions. Our services include precision diagnostics, hydraulic rod machining, seal replacement, pressure testing, and hard chrome plating all tailored to reduce downtime, extend equipment life, and maintain operational efficiency.

Precision Repairs That Prevent Extended Downtime

Downtime from a faulty hydraulic cylinder can result in halted production lines, missed delivery commitments, and expensive emergency service calls. Over time, these disruptions can also cause damage to other mechanical systems, increasing overall repair costs and affecting safety compliance. Our mission is to eliminate such risks through a structured, quality-assured approach to hydraulic repair and maintenance.

Our repair process begins with a rapid and accurate diagnosis. Our experienced technicians use advanced tools and inspection methods to identify the root cause of hydraulic failure, whether it’s due to rod scoring, seal leakage, misalignment, or pressure instability. Once diagnosed, we disassemble the cylinder for a full inspection of all internal and external components, including bores, seals, grooves, and rods.

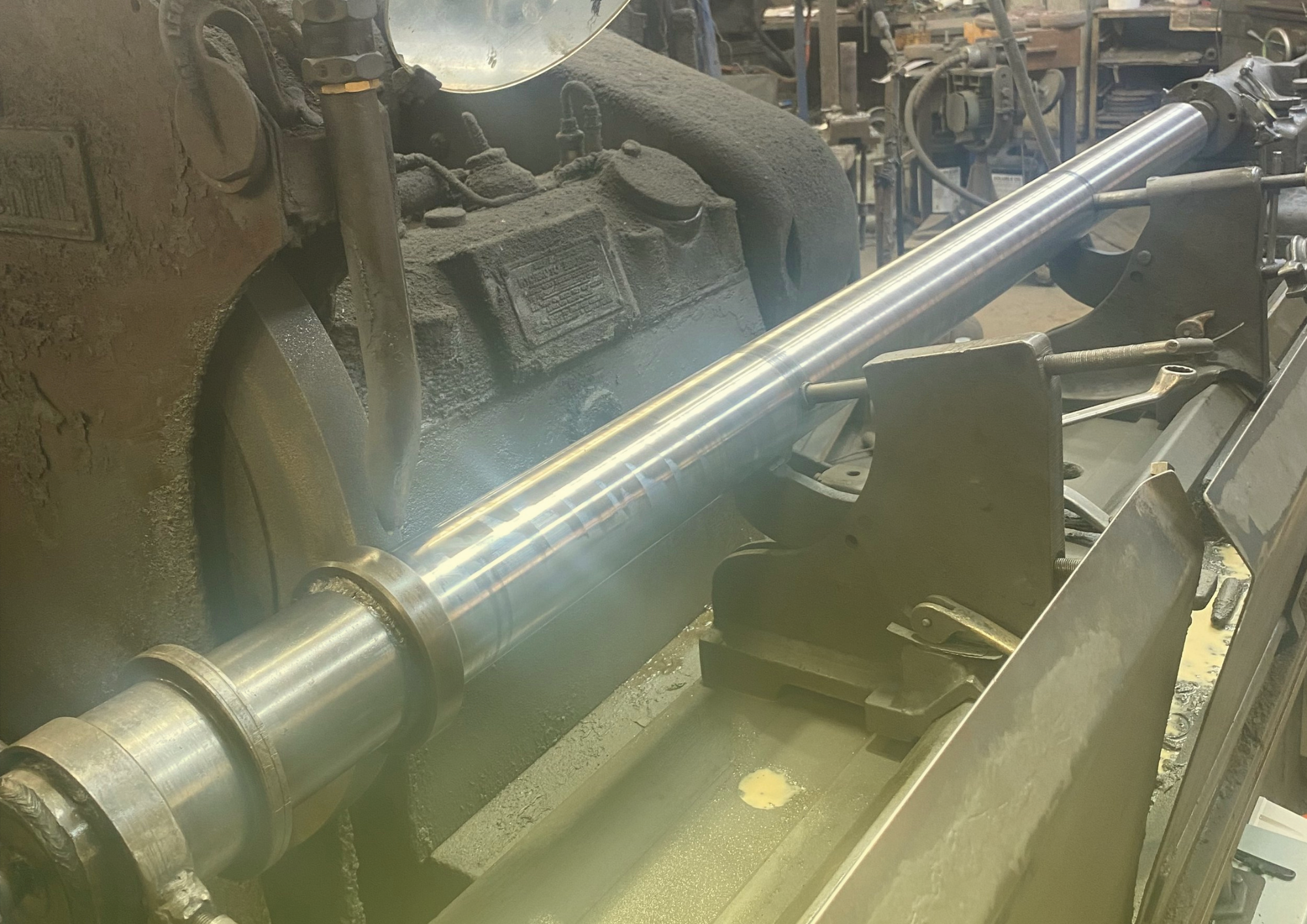

Rod machining is one of the most critical elements in restoring functionality. At Gaja Engineering, we use state-of-the-art lathes and grinders to restore hydraulic rods to their original straightness and diameter, ensuring they meet OEM tolerances. We also replace seals with OEM-grade polyurethane, nitrile, or PTFE components designed to withstand high-pressure and temperature conditions, ensuring long-term reliability.

Integrated Hard Chrome Plating and End-to-End Testing

One of our core services at Gaja Engineering is hard chrome plating, offered through our in-house division, HardChrome Services, a proud part of our group. This plating process enhances the durability, wear resistance, and corrosion protection of hydraulic rods. It also improves sealing performance, reducing fluid leakage risks. Because the plating is managed internally, we maintain tighter tolerances, reduce turnaround times, and ensure consistent quality throughout the repair process.

After cylinder reassembly, each unit undergoes comprehensive pressure testing and inspection, verifying that it meets or exceeds operational ratings. This guarantees leak-free operation and compliance with safety and performance standards—critical for sectors like industrial servicing Adelaide, logistics engineering, and mining equipment maintenance.

Choosing professional hydraulic cylinder repair over full replacement can reduce downtime by up to 50% and extend component lifespan significantly. Our hard chrome finishes improve seal longevity and minimize ongoing maintenance. The result is a lower total cost of ownership (TCO) and a more reliable operation.

Our services are ideal for industries where uptime is essential. In mining, logistics, and infrastructure, equipment must operate consistently under high stress. Our South Australia-based team brings hands-on experience and fast mobilization to meet the specific needs of Adelaide’s industrial sector.

We also offer preventative maintenance through HardChrome Services, including scheduled inspections, seal checks, rod assessments, and pressure evaluations. These measures detect early wear, helping prevent failures and unplanned downtime.

As an AS-certified provider with a fully equipped workshop, Gaja Engineering handles everything in-house—from diagnostics and machining to plating and final testing. Our documentation and quality standards ensure our clients meet internal and external compliance requirements with confidence.

In addition to servicing hydraulic cylinders, we offer a range of support capabilities, including:

-

Hydraulic rod straightening and polishing

-

Barrel honing and concentricity correction

-

Seal replacement and lubrication system optimization

-

Custom fabrication of rods and pistons

-

OEM-spec component replacement

Every service is tailored to meet the specific hydraulic pressures, environments, and duty cycles of your machinery. Our aim is to not only repair but enhance the performance and lifespan of your hydraulic assets.

If you’re considering whether repair or replacement is the right option, we’re happy to provide technical guidance, cost comparisons, and inspection services. With Gaja Engineering and HardChrome Services working as one cohesive team, you can count on precision-driven outcomes from start to finish.

Ready to Reduce Downtime and Extend Equipment Life?

Whether you’re dealing with unexpected cylinder failure or planning routine servicing, Gaja Engineering is your trusted partner for hydraulic cylinder, proudly serving industrial clients in Adelaide and throughout South Australia.

We invite you to reach out for a detailed assessment, customized quote, or to learn more about our integrated services including machining, plating, testing, and preventative maintenance. With our commitment to precision and our fully integrated HardChrome sevices, your hydraulic systems are in capable hands.

📧 Email: info@gajaengg.com.au

🌐 Website: www.gajaengg.com.au

🌐 Website:www.hardchromeservices.com.au

Frequently asked questions

How long does a standard repair take?

Most cylinders can be fully refurbished within 1–3 business days, depending on damage severity and plating requirements.

Is hard chrome plating always required?

Not always. It’s used when the rod has deep scoring or corrosion. Otherwise, machining and polishing may be sufficient.

Can repairs be done on-site in Adelaide?

Yes. We offer mobile diagnostic and repair support, reducing transport time and minimizing disruption.

Will repairs affect OEM warranty?

In most cases, no. We follow strict protocols and provide documentation that aligns with OEM service requirements.

Are refurbished cylinders as reliable as new ones?

Absolutely. With proper testing and reconditioning, refurbished cylinders often outperform new components in durability and precision

What industries do you serve in Adelaide?

We work with clients in mining, infrastructure, logistics, utilities, and manufacturing, providing both reactive and preventative hydraulic support