In today’s competitive manufacturing environment, efficiency, precision, and speed are non-negotiable. CNC mill-turn technology has emerged as a game-changer—combining milling and turning operations into a single, streamlined process. For industries demanding tight tolerances and complex geometries, this approach delivers measurable gains in productivity and quality.

At Gaja Engineering, we leverage advanced CNC mill-turn capability as a core part of our engineering and fabrication services in Adelaide, helping clients reduce lead times while maintaining uncompromising accuracy.

What Is CNC Mill-Turn Technology?

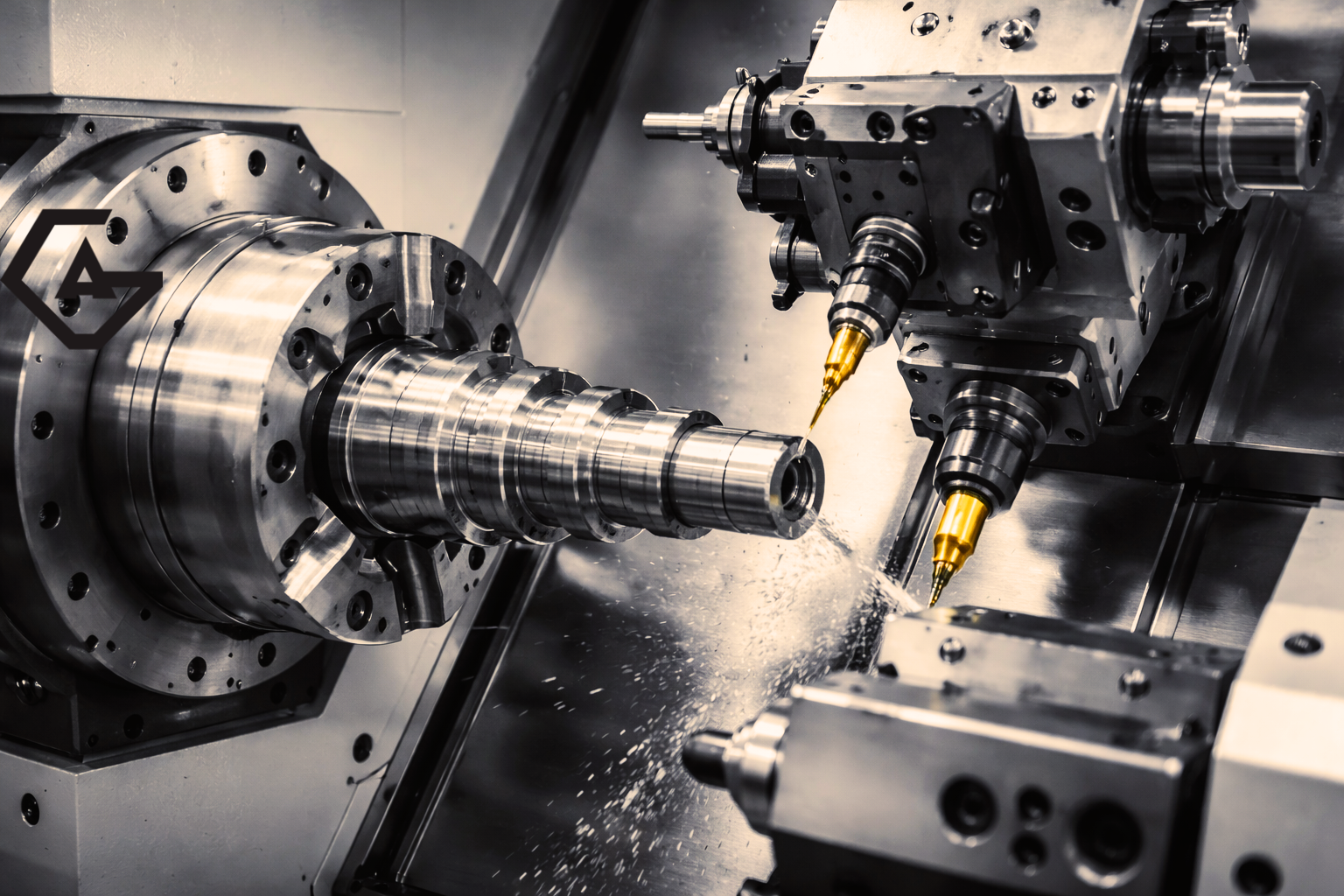

CNC mill-turn machines integrate traditional turning functions with live milling tools, allowing multiple operations to be completed in one setup. This eliminates the need to transfer parts between machines, significantly reducing handling errors and downtime.

For complex components—especially those requiring angled holes, slots, contours, or multi-face machining—mill-turn technology delivers consistent, repeatable results in a single workflow.

Workflow Efficiency: Where the Real Value Lies

The true advantage of mill-turn machining is workflow optimisation. By consolidating operations:

-

Setup time is reduced, improving overall machine utilisation

-

Part accuracy increases by eliminating re-clamping and alignment errors

-

Production cycles shorten, enabling faster turnaround

-

Labour dependency decreases, improving cost efficiency

This integrated approach aligns perfectly with modern lean manufacturing principles—doing more in less time, with fewer variables.

Real-World Applications Across Industries

CNC mill-turn technology is ideal for:

-

Mining and heavy equipment components

-

Industrial shafts, couplings, and housings

-

Hydraulic and pneumatic parts

-

Custom fabrication and low-volume precision runs

At Gaja Engineering, our mill-turn workflow supports both prototype development and repeat production, making it a flexible solution for diverse fabrication demands.

Why Mill-Turn Matters for Adelaide Manufacturers

Local industries in Adelaide demand reliability, fast response times, and engineering expertise. By investing in advanced mill-turn machining, Gaja Engineering ensures our clients benefit from:

-

Shorter lead times

-

Reduced rework and scrap

-

Consistent quality across batches

-

Scalable production capability

This is how modern Engineering and Fabrication services in Adelaide stay competitive in a global supply chain.

Gaja Engineering’s Approach

Our CNC mill-turn processes are backed by skilled machinists, rigorous quality checks, and engineering-led planning. Every job is approached with efficiency in mind—optimising tool paths, reducing waste, and delivering parts that meet exact specifications.

Frequently Asked Questions (FAQ)

1. What is CNC mill-turn machining?

It is a process that combines milling and turning in one machine to complete complex parts efficiently.

2. How does mill-turn improve workflow efficiency?

By reducing multiple setups, handling time, and machine transfers.

3. Is mill-turn suitable for custom fabrication?

Yes, it’s ideal for both one-off custom parts and repeat production.

4. What industries benefit most from mill-turn technology?

Mining, manufacturing, hydraulics, and industrial engineering sectors.

5. Does mill-turn machining reduce production costs?

Yes, fewer setups and faster cycles lead to lower overall costs.

6. Why choose Gaja Engineering for mill-turn services?

Because we combine advanced machinery with proven Engineering and Fabrication services in Adelaide, delivering precision, reliability, and value.