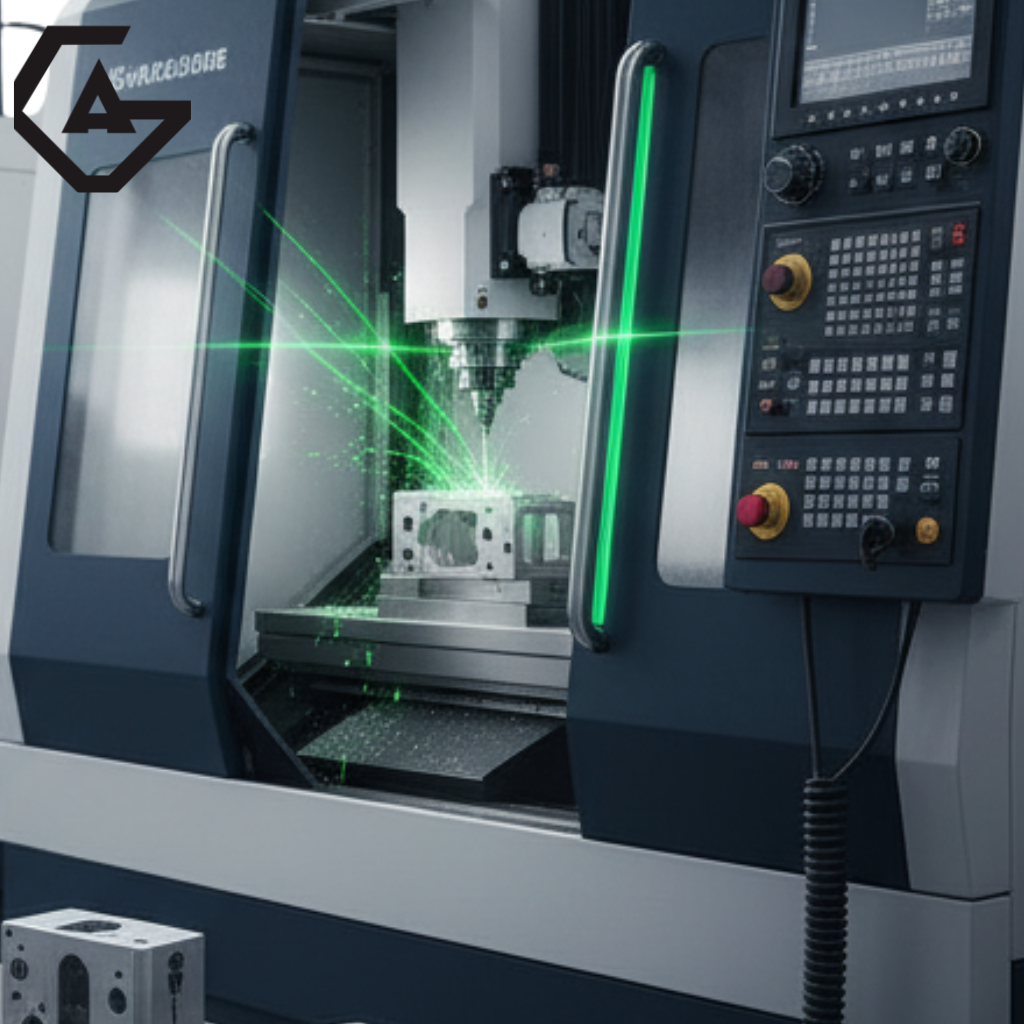

In the defence industry, precision isn’t optional—it’s the standard. At Gaja Engineering, our CNC 3-axis and 4-axis machining capabilities ensure unmatched accuracy and consistency for aluminium and steel components that power Australia’s advanced defence systems.

3-Axis CNC Machining: Efficiency & Consistency

Our 3-axis machining delivers exceptional precision for flat, contoured, and prismatic components. It’s ideal for producing brackets, housings, and defence enclosures where accuracy and repeatability define performance

4-Axis CNC Machining: Complexity Made Simple

When components demand intricate geometry or angular features, our 4-axis CNC machining provides a decisive advantage. The additional rotational axis allows for multi-sided machining in a single setup—reducing production time and maintaining tolerance integrity

Materials that Meet Mission Standards

From high-strength aluminium alloys to robust steel grades, Gaja Engineering’s machining process maintains the strength, surface integrity, and dimensional accuracy required for defence-grade reliability.

Why Defence Clients Choose Gaja Engineering

Based in Adelaide, our facility integrates advanced CNC technology, skilled operators, and stringent quality inspection to meet the Australian Defence Standard (ASDEFCON) requirements. We take pride in contributing to Australia’s strategic manufacturing excellence through precision, reliability, and local expertise.

Frequently Asked Questions (FAQ)

1. What is the difference between 3-axis and 4-axis CNC machining?

3-axis machining moves along three linear axes (X, Y, Z), while 4-axis adds rotation, allowing complex multi-face machining in one setup.

2. Why is 4-axis machining ideal for defence parts?

It enables high-precision machining of intricate components used in aerospace and military assemblies.

3. What materials does Gaja Engineering machine for defence projects?

We specialize in aluminium alloys and steel grades suited for strength, weight efficiency, and durability.

4. How does CNC machining improve component reliability?

Automated control ensures consistent accuracy, repeatability, and quality—essential for mission-critical defence systems.

5. Does Gaja Engineering provide prototype and production services?

Yes, we support both prototype development and large-scale production runs for defence applications.

6. How to contact Gaja Engineering?

please Visit Gaja Engeneering Website and Fill the contact form. You can also follow Gaja Engeneering on our Social media pages. Thank you.