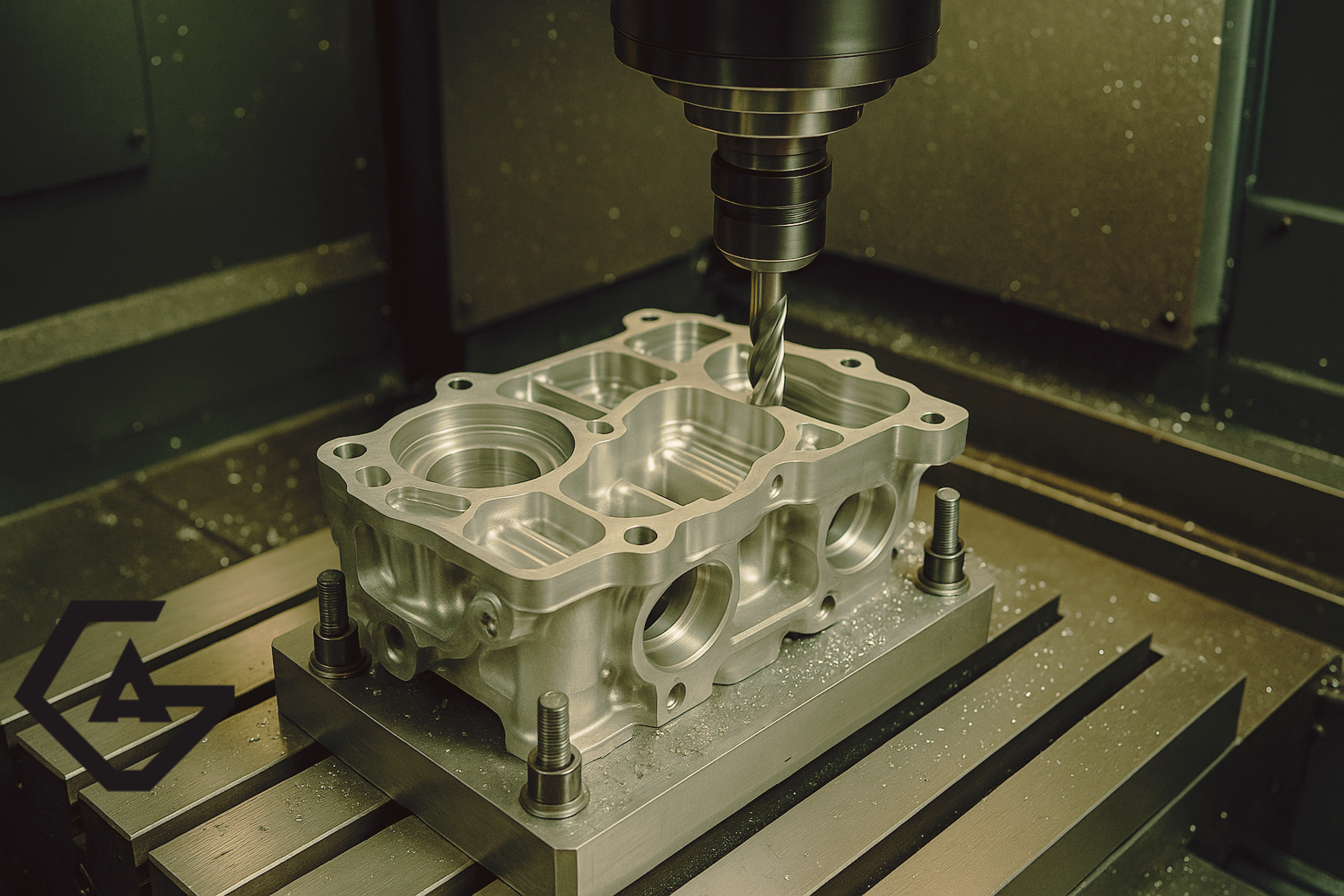

Automotive innovation moves fast—and manufacturers who want to stay ahead need partners that deliver precision, speed and repeatability at scale. That’s exactly where Gaja Engineering steps in. With decades of engineering heritage and advanced CNC capability, we simplify the entire automotive prototyping process using high-accuracy CNC milling designed for real-world performance.

Today, automotive OEMs, aftermarket brands and performance engineering teams rely on CNC Machining Adelaide to transform ideas into functional prototypes with unmatched precision. Whether it’s a single custom component or a pre-production batch run, CNC milling ensures consistency and dimensional accuracy that traditional processes simply can’t achieve.

Why CNC Milling Is the Backbone of Modern Automotive Prototyping

1. Exceptional Precision for Complex Geometries

Automotive designs often demand extremely tight tolerances—especially for engine components, brackets, housings, and performance parts. CNC milling delivers micron-level accuracy, helping Gaja Engineering produce components that fit and function perfectly from the first iteration.

2. Faster Turnaround to Accelerate Development

In the automotive sector, time saved in prototyping equals faster time-to-market. CNC milling dramatically cuts lead times, enabling engineers to test, redesign and validate components rapidly. Our CNC Machining Adelaide facility is optimised for quick setups and efficient production cycles.

3. Material Flexibility for All Automotive Needs

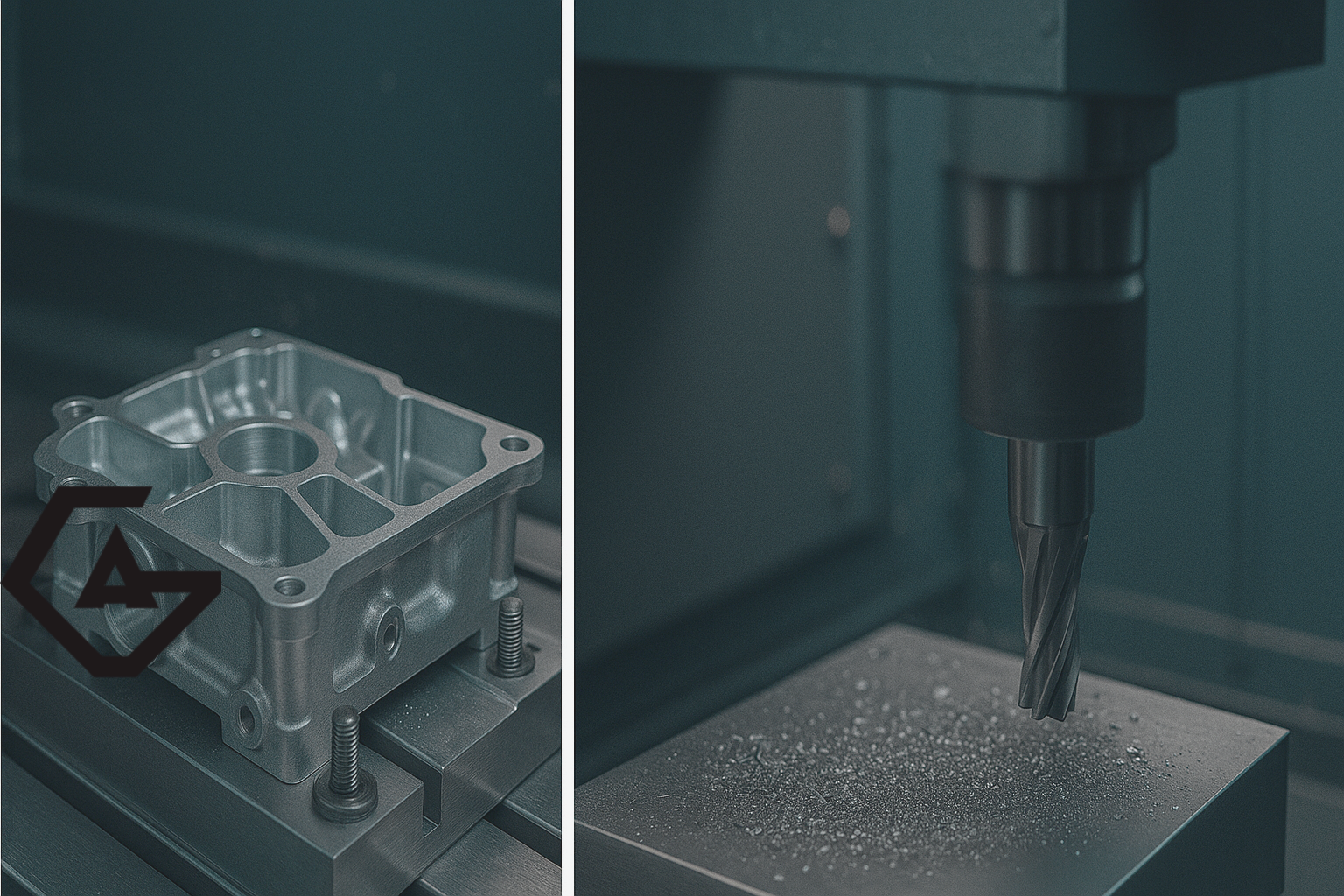

From aluminium and stainless steel to engineering plastics and composites, CNC milling supports a wide range of automotive-grade materials. This gives designers full freedom to test strength, durability, weight and thermal performance without compromise.

4. Repeatability for Pre-Production Runs

Once a design is approved, CNC milling ensures every unit in the batch matches the approved prototype. Gaja Engineering’s automated workflows maintain reliability and consistency, whether you need 1 part or 1,000.

How Gaja Engineering Simplifies Automotive Prototyping

At Gaja Engineering, our approach blends advanced CNC technology with practical engineering experience. Every prototype is crafted with precision, backed by quality checks and process standardisation.

Our team supports automotive clients across:

-

custom component development

-

rapid prototyping

-

fixture and bracket machining

-

engine & drivetrain components

-

performance upgrades

-

motorsport-grade machining

By integrating CNC Machining Adelaide into your product development workflow, your team gains a competitive edge with parts that are both production-ready and cost-efficient.

Frequently Asked Questions (FAQ)

1. Why is CNC milling ideal for automotive prototyping?

Because it delivers precise, repeatable and complex components that meet strict automotive tolerances.

2. How fast can Gaja Engineering deliver CNC-machined prototypes?

Lead times depend on complexity, but our streamlined CNC workflows allow rapid turnaround for most prototypes.

3. Which materials can be used for automotive CNC milling?

Aluminium, stainless steel, mild steel, plastics, brass, and engineered alloys commonly used in automotive applications.

4. Can CNC machining support motorsport or performance vehicle components?

Yes. CNC milling is widely used in motorsport due to its precision, strength and performance consistency.

5. What industries does Gaja Engineering serve apart from automotive?

Food manufacturing, construction, mining, agriculture, industrial engineering and custom fabrication sectors.

6. Does CNC Machining Adelaide support batch production or only prototyping?

Both. Gaja Engineering handles one-off prototypes as well as small or medium production runs with full quality control.