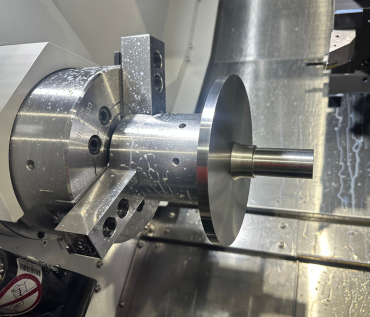

Our 4 axis machine centres use a variety of specialised rotating cutters and drills to carry out a huge range of machining operations in metals, alloys and more, that are cost effective and within strict size tolerances.

Our 4 axis machine centres use a variety of specialised rotating cutters and drills to carry out a huge range of machining operations in metals, alloys and more, that are cost effective and within strict size tolerances.

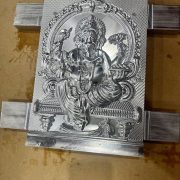

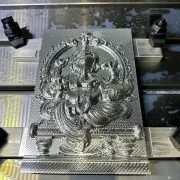

While accomplishing jobs like drilling holes, milling flats, grooving, thread tapping, and 3D contouring, our machines are able to quickly take something such as a single block of metal and produce a high quality intricately machined product.

Some of the common milling jobs we undertake are Moulds, plate work, housings, prototyping, product rework and modification, components, replacement, and spare parts.