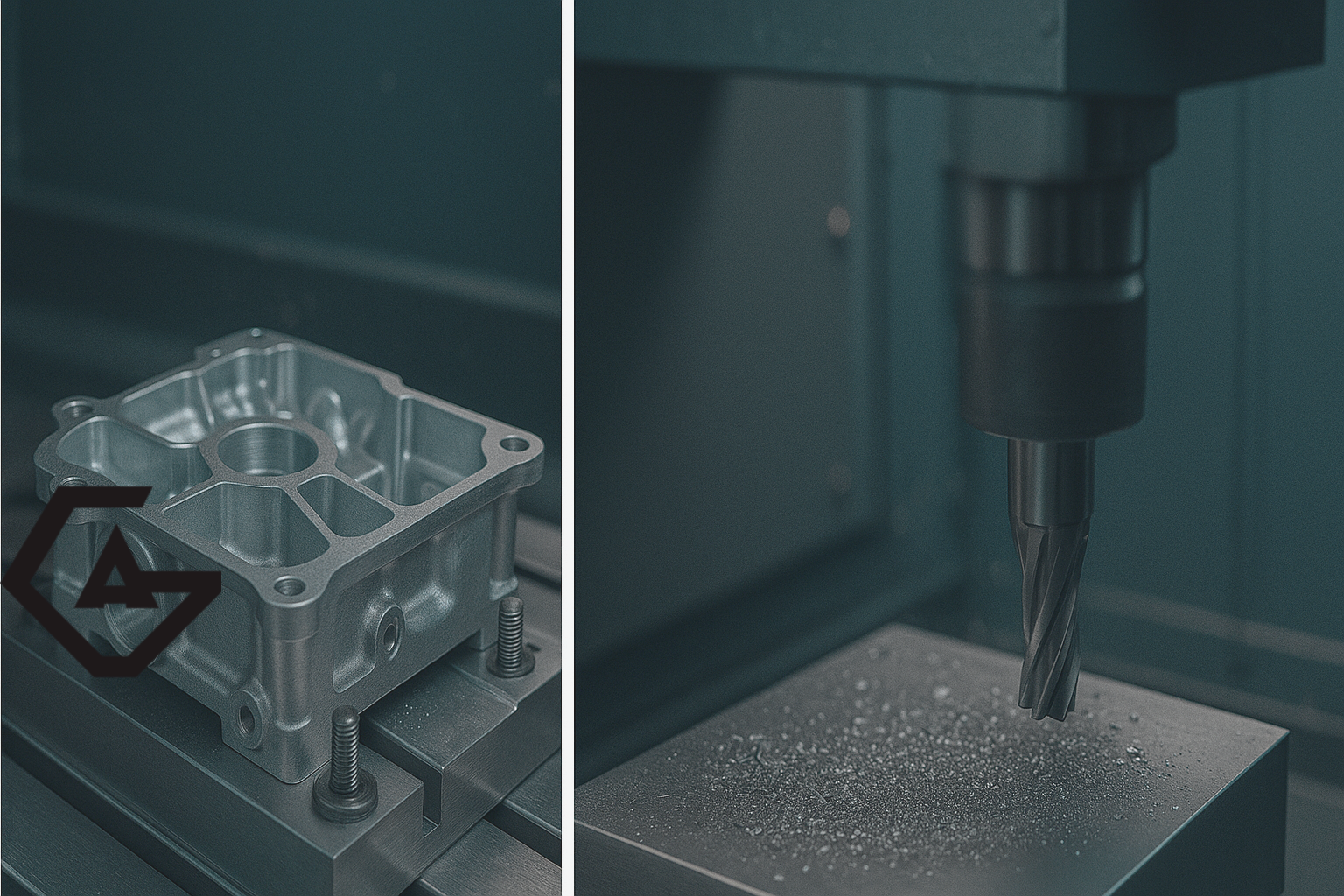

In today’s high-precision manufacturing environment, complex geometries are no longer the exception—they’re the standard. Aerospace brackets, medical components, defence parts, and specialised industrial tooling all demand tighter tolerances, fewer setups, and superior surface finishes. This is where multi-axis CNC milling becomes a decisive advantage.

At Gaja Engineering, our CNC machining services in Adelaide are built around advanced 4-axis and 5-axis milling strategies that allow us to machine intricate components efficiently, accurately, and repeatably.

Why Multi-Axis CNC Milling Matters

Traditional 3-axis machining often requires multiple setups, manual repositioning, and secondary operations. Each additional setup increases cycle time and introduces alignment risk. By contrast, 4-axis and 5-axis CNC machining enables continuous tool engagement from multiple angles in a single setup—critical for complex geometries.

For manufacturers seeking consistent quality and shorter lead times, multi-axis CNC milling is not just an upgrade; it’s a strategic necessity.

4-Axis vs 5-Axis CNC Milling: Strategic Use Cases

4-Axis CNC Milling

In 4-axis machining, the workpiece rotates around one additional axis, making it ideal for components with features around a central axis—such as slots, holes, and profiles on cylindrical or prismatic parts. At Gaja, 4-axis strategies are frequently used to reduce setups while maintaining cost efficiency for medium-complexity components.

5-Axis CNC Milling

5-axis machining adds simultaneous movement across two rotary axes, allowing the cutting tool to approach the part from virtually any direction. This is essential for:

-

Undercuts and compound angles

-

Sculpted surfaces and organic shapes

-

Tight internal features

-

High-tolerance aerospace and medical components

Our 5-axis CNC machining capability enables shorter tools, better surface finishes, and reduced tool wear—key factors in precision CNC machining services in Adelaide.

Best-Practice Programming Strategies from the Gaja Workshop

-

Design-for-Manufacture (DFM) Alignment

We collaborate early with clients to optimise CAD models for multi-axis machining, reducing unnecessary complexity while preserving function. -

Toolpath Optimisation

Advanced CAM strategies such as adaptive clearing, swarf cutting, and simultaneous 5-axis contouring are used to maintain consistent chip load and surface quality. -

Single-Setup Machining

Wherever possible, components are completed in one setup to eliminate cumulative tolerance errors and improve repeatability. -

Collision-Aware Simulation

Every program is digitally simulated to validate toolpaths, fixture clearances, and axis limits—critical for complex geometries. -

Material-Specific Strategies

From aluminium and stainless steel to high-strength alloys, cutting parameters are tailored to material behaviour and part geometry.

Why Choose Gaja Engineering for CNC Machining Services in Adelaide

Our workshop combines advanced CNC technology with hands-on machining expertise. Every component is approached with a production mindset—balancing precision, efficiency, and cost control. That’s how Gaja Engineering consistently delivers reliable CNC machining services in Adelaide for demanding industries.

Frequently Asked Questions (FAQ)

1. What industries benefit most from 5-axis CNC machining?

Aerospace, defence, medical, automotive, and advanced industrial manufacturing.

2. Is 5-axis CNC machining more expensive than 3-axis?

While machine time may be higher, overall costs often drop due to fewer setups and faster production.

3. When is 4-axis machining sufficient?

For parts with features around a single rotational axis where full 5-axis motion isn’t required.

4. Can multi-axis machining improve surface finish?

Yes. Shorter tools and optimal tool angles significantly enhance surface quality.

5. Does Gaja Engineering handle prototype and production runs?

Absolutely. We support one-off prototypes through to repeat production.

6. How accurate is multi-axis CNC machining?

With proper programming and setup, tolerances of ±0.01 mm are achievable depending on material and geometry.