In today’s high-performance manufacturing landscape, complexity is no longer the exception—it’s the expectation. Industries demand tighter tolerances, faster turnaround, and components that perform reliably under extreme conditions. This is where multi-axis machining becomes a strategic advantage.

At Gaja Engineering, multi-axis CNC machining is a core capability that strengthens our reputation in engineering and fabrication in Adelaide, particularly for complex, precision-driven components.

What Is Multi-Axis Machining?

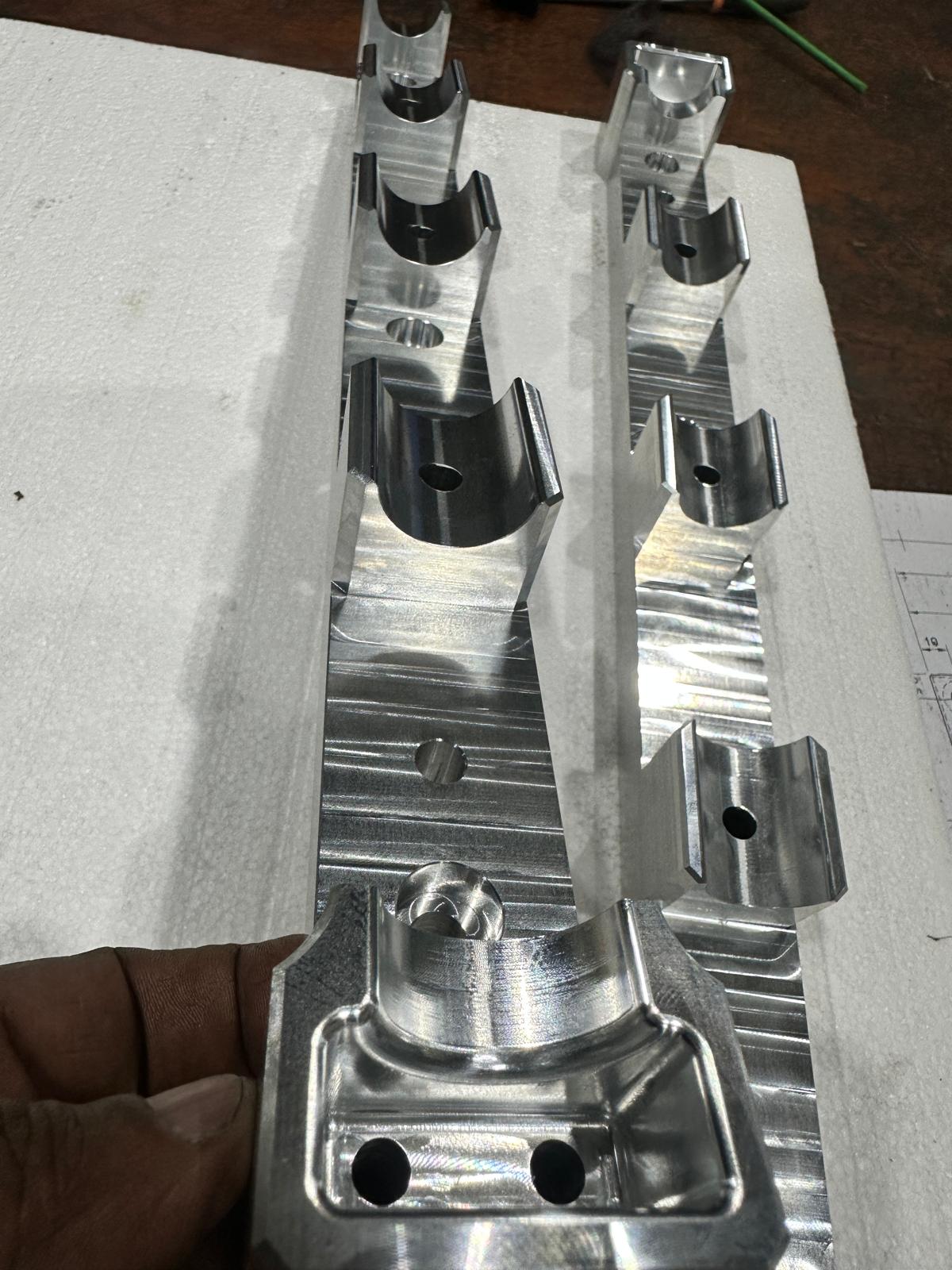

Unlike traditional 3-axis machining, multi-axis machining (4-axis, 5-axis and beyond) allows simultaneous movement across multiple planes. This enables intricate geometries, undercuts, compound angles, and complex profiles to be machined in a single setup.

For clients, this translates to higher accuracy, reduced handling, and improved structural integrity.

Why Multi-Axis Machining Matters for Complex Components

Complex components often fail not due to material issues, but due to dimensional inaccuracies and weak machining transitions. Multi-axis machining addresses these challenges by:

-

Ensuring consistent surface finishes

-

Maintaining tight tolerances across complex geometries

-

Reducing production lead times

For sectors such as mining, defence, food processing, automotive, and heavy engineering, this level of precision is non-negotiable.

Gaja Engineering’s Strategic Advantage

Gaja Engineering integrates advanced multi-axis CNC technology with hands-on engineering expertise. This combination allows us to move beyond basic fabrication and deliver value-engineered solutions.

Our approach includes:

-

Process optimisation to reduce cycle time

-

Design-for-manufacture input to improve component lifespan

-

Precision inspection at every critical stage

This capability positions Gaja Engineering as a preferred partner for engineering and fabrication in Adelaide, especially where complexity and reliability are mission-critical.

Reduced Setups, Increased Accuracy

One of the key commercial benefits of multi-axis machining is reduced setups. Fewer setups mean:

-

Lower cumulative error

-

Improved repeatability

-

Better cost efficiency for complex runs

For clients, this results in components that fit right the first time—saving downstream assembly and maintenance costs.

Supporting Local Manufacturing in Adelaide

By investing in advanced machining capabilities locally, Gaja Engineering supports Australian manufacturing resilience. Clients benefit from shorter lead times, responsive collaboration, and direct access to engineering teams—without relying on offshore suppliers.

This local advantage reinforces why businesses seeking engineering and fabrication in Adelaide partner with Gaja Engineering for high-complexity work.

Built for Performance, Engineered for Confidence

Multi-axis machining is not just about technology—it’s about execution. At Gaja Engineering, every component is machined with a performance-first mindset, ensuring reliability in real-world operating conditions.

Frequently Asked Questions (FAQ)

1. What industries benefit most from multi-axis machining?

Industries requiring high precision such as mining, defence, food manufacturing, and automotive benefit significantly.

2. Is multi-axis machining more accurate than traditional CNC machining?

Yes. Fewer setups and continuous tool paths result in superior accuracy and consistency.

3. Does multi-axis machining reduce production time?

In most complex components, yes. Single-setup machining significantly shortens lead times.

4. Can Gaja Engineering handle custom one-off components?

Absolutely. Our multi-axis capability is ideal for prototypes and low-volume precision runs.

5. Is multi-axis machining cost-effective for complex parts?

While machine rates are higher, reduced rework and faster turnaround often lower total project cost.

6. Why choose Gaja Engineering for engineering and fabrication in Adelaide?

Because we combine advanced CNC technology with local expertise, quality control, and responsive service.