Mining environments are unforgiving. Heavy loads, abrasive materials, continuous vibration, and extreme temperatures place enormous stress on every component within a machine. When critical parts fail, entire operations come to a halt—costing hours of lost productivity and significant financial impact. This is why mining companies increasingly rely on CNC Machining Adelaide to ensure their high-wear components are engineered for maximum durability and long-term performance.

At the forefront of this capability is Gaja Engineering, a precision-driven manufacturing partner delivering industrial-grade machining services for mining, defence, and heavy equipment sectors.

Why CNC Precision Matters in Mining Operations

Mining machinery like crushers, draglines, drill rigs, slurry pumps, conveyors, and earthmoving equipment operate in extreme conditions. These parts must withstand:

-

Abrasion from rocks, ores, and slurry

-

Heat and continuous load cycles

-

High-impact forces

-

Corrosive environments

Traditional machining methods fall short when it comes to tolerance accuracy and material consistency. Instead, precision machining, heavy equipment machining, and industrial CNC services ensure that every part is engineered to perform reliably—even under the harshest pressures.

Gaja Engineering’s CNC Advantage for High-Wear Mining Components

1. Industrial-Grade Accuracy for Extreme Loads

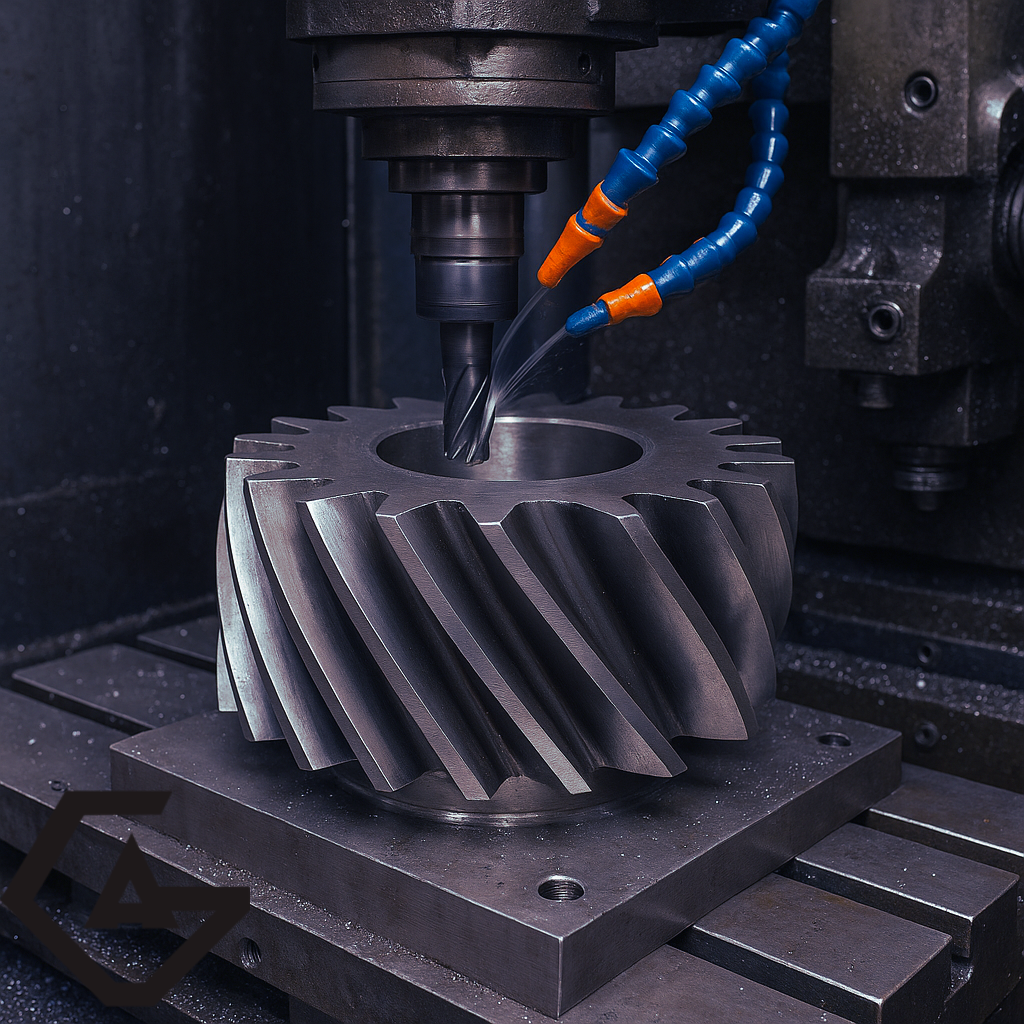

Using advanced 3-axis and 4-axis CNC milling and turning systems, Gaja Engineering machines components to micron-level precision. This level of accuracy significantly improves the lifespan of critical parts such as bushings, shafts, gear housings, wear plates, brackets, couplings, and structural components.

2. Materials Built for Harsh Mining Conditions

Our machining processes work seamlessly with high-tensile steels, alloy steels, cast iron, aluminium alloys, and custom industrial materials—ensuring long-lasting strength and resistance against fatigue and abrasion.

3. Enhanced Component Durability & Reduced Downtime

Quality machining reduces the risk of:

-

Premature wear

-

Misalignment issues

-

Performance inefficiencies

-

Unexpected equipment shutdowns

This directly lowers maintenance costs and increases uptime—key metrics for mining productivity.

4. Custom Machining for Specialised Mining Needs

Mining operations often require one-off parts or custom replacements. Gaja Engineering provides:

-

Prototype machining

-

Low-volume custom runs

-

High-volume production

-

Reverse engineering for obsolete components

5. Seamless Integration With Your Existing Systems

Every machined component is manufactured to match your required tolerances, OEM specifications, and operational demands. This ensures drop-in compatibility without modification.

Why Gaja Engineering Leads the Way

-

Advanced CNC infrastructure with multi-axis machining

-

Experienced machinists and engineering specialists

-

Material-specific machining for defence and mining applications

-

In-house quality inspection and documentation

-

Surface finishing and assembly support for end-to-end service

Gaja Engineering’s legacy lies in delivering Australian-made precision components that uphold industry standards and empower large-scale operations nationwide.

Explore Our Expertise

At Gaja Engineering, we believe that CNC machining for defence and mining sectors is not just about cutting metal—it’s about building reliability into every millimetre. Our commitment to accuracy, endurance, and quality assurance sets us apart in the manufacturing landscape.

Frequently Asked Questions (FAQ)

1. Why is CNC Machining Adelaide important for mining operations?

It ensures components are built with high precision and durability, enabling mining equipment to withstand extreme mechanical and environmental stress.

2. What kind of mining parts can Gaja Engineering machine?

Shafts, wear plates, pump housings, gear components, couplings, brackets, bushings, and other high-wear parts across crushers, conveyors, and drilling systems.

3. How does CNC machining improve part longevity?

By delivering precise tolerances, superior finishes, and material consistency—resulting in less friction, lower wear, and improved lifecycle.

4. Can you manufacture custom or one-off parts?

Yes. We specialise in custom machining, prototypes, replacement parts, and components not available off the shelf.

5. Do machined parts reduce downtime in mining operations?

Absolutely. Durable, precisely machined parts minimise breakdowns and reduce overall maintenance frequency.

6. Is Gaja Engineering compliant with industry standards?

Yes. All machining adheres to strict engineering, safety, and quality guidelines for mining and industrial applications.