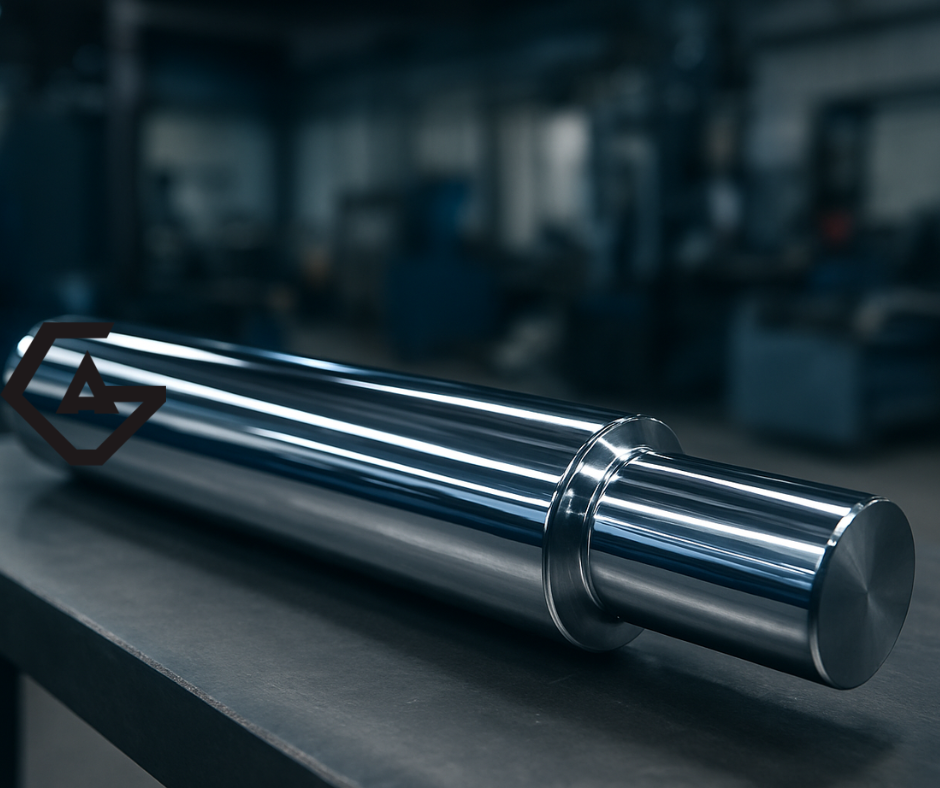

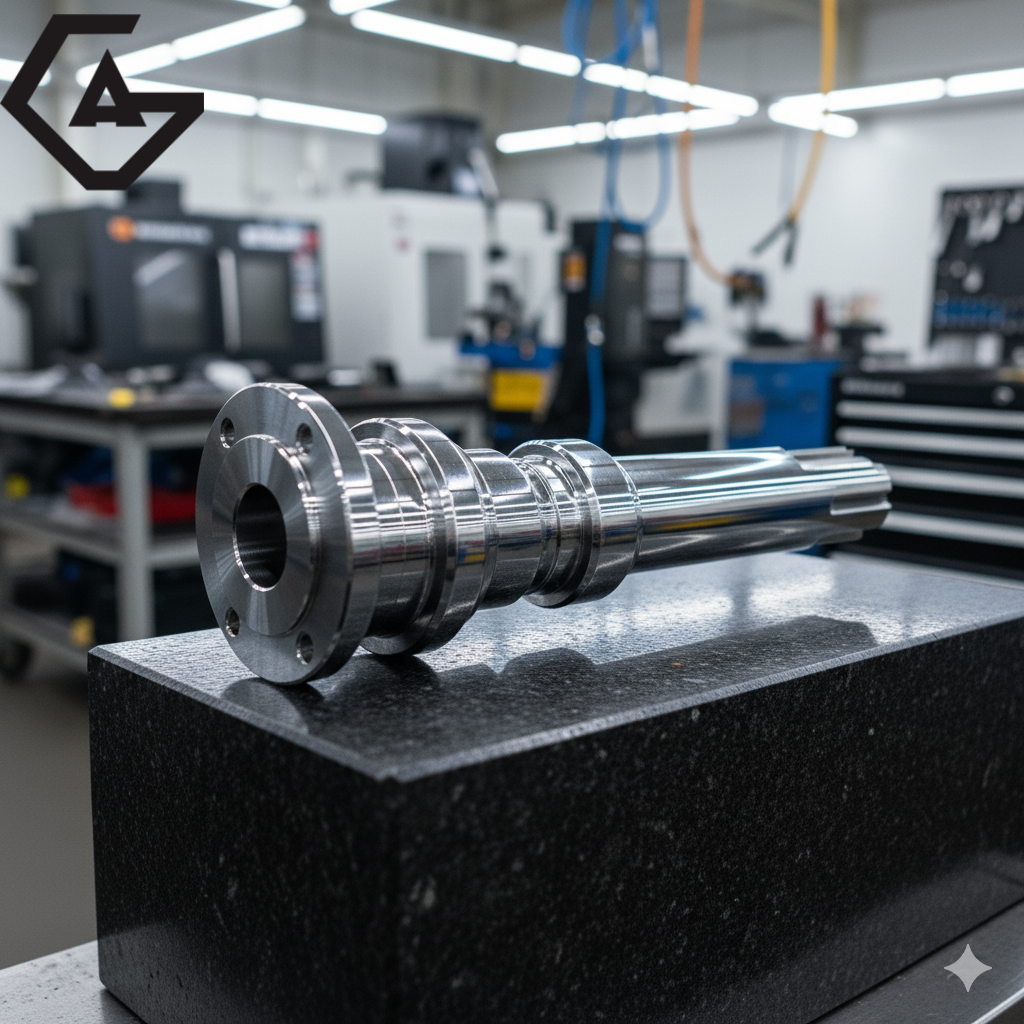

In precision engineering, every micron counts. Once chrome plating is complete, many assume the job is done — but for parts that demand the highest surface quality, polishing after chrome plating can make a significant difference. Whether it’s for hydraulic rods, rollers, or high-performance machinery components, this final finishing step enhances not just the look, but the lifespan and performance of your parts.

Why Consider Polishing After Chrome Plating?

Chrome plating provides a durable, corrosion-resistant surface, but the process alone may leave microscopic imperfections or slight texture variations. Polishing after chrome plating smooths out these irregularities, resulting in a mirror-like finish and improved wear resistance.

At Gaja Engineering, we often recommend polishing for applications where components experience high friction, tight tolerances, or aesthetic exposure. It’s not just about appearance — it’s about optimizing performance.

When Is Polishing Necessary?

-

Precision or High-Speed Applications

When components such as hydraulic rods, piston shafts, or aerospace parts operate at high speeds, surface roughness can lead to friction and heat build-up. Polishing reduces this, improving motion efficiency and service life. -

Corrosion or Environmental Exposure

For parts exposed to moisture, chemicals, or outdoor environments, a polished chrome layer offers better sealing and corrosion protection. -

Aesthetic Requirements

Architectural and decorative chrome finishes often demand a flawless, reflective surface — achieved only with post-plating polishing. -

Repair or Rework Jobs

Re-chromed or refurbished components may need polishing to restore uniformity and eliminate visible transition lines.

Benefits of Polishing After Chrome Plating

-

Enhanced Surface Finish: Achieve a smoother, more uniform surface with reduced micro-roughness.

-

Increased Durability: Lower friction reduces wear and tear, extending component life.

-

Improved Corrosion Resistance: Polished chrome seals pores and prevents early corrosion.

-

Better Aesthetics: A bright, mirror-like appearance suitable for visible assemblies.

-

Superior Performance: Improved motion, sealing, and contact precision for high-tolerance assemblies.

Gaja Engineering’s Expertise in Chrome Finishing

With decades of experience in surface engineering, Gaja Engineering combines hard chrome plating with precision polishing to deliver finishes that meet critical industry standards. Our team understands how the right post-treatment can elevate part performance—ensuring quality and reliability across industrial, mining, and manufacturing applications.

Frequently Asked Questions (FAQ)

1. Why is polishing needed after chrome plating?

Polishing smooths out micro-imperfections, improves the surface finish, and enhances both durability and corrosion resistance.

2. Does polishing affect the thickness of chrome plating?

A controlled polishing process removes only minor surface irregularities, maintaining overall plating thickness and integrity.

3. What industries benefit most from polished chrome surfaces?

Hydraulic, mining, automotive, aerospace, and manufacturing sectors often require polished chrome finishes for efficiency and performance.

4. Can all chrome-plated parts be polished?

Yes, most chrome-plated components can be polished, but the technique and abrasives used depend on the part’s geometry and application.

5. Does polishing increase the cost significantly?

While it adds a small additional cost, polishing offers long-term savings through extended part life and reduced maintenance needs.

6. Who can I trust for expert chrome polishing services?

Gaja Engineering provides professional polishing after chrome plating, ensuring each part meets precise performance and quality standards.